Structural Steel Earthing

Structural steel earthing is a crucial aspect of any construction project, but it is often overlooked. In this article, we will discuss the importance of structural steel earthing and how it can ensure the safety and longevity of your building.

The Pain Points of Structural Steel Earthing

Structural steel earthing can be a daunting task for many construction professionals. It involves dealing with complex electrical systems, calculating the right amount of grounding material, and ensuring that the system is installed correctly. However, neglecting this aspect of the project can lead to serious safety hazards, legal liabilities, and damage to equipment.

What is the Target of Structural Steel Earthing?

Structural steel earthing is aimed at protecting people and equipment from electrical hazards by providing a low-resistance path for any electric currents that may be present in the building's electrical system. The goal is to prevent electrical shock and ensure that equipment is not damaged by stray electrical currents.

Summary of Structural Steel Earthing

To summarize, structural steel earthing is a critical aspect of any construction project that involves electrical systems. By ensuring that the grounding system is correctly installed and maintained, you can prevent safety hazards, legal liabilities, and damage to equipment.

The Benefits of Proper Structural Steel Earthing

In my experience, I have seen first-hand the benefits of proper structural steel earthing. Not only does it ensure the safety of the building's occupants, but it also helps to extend the life of electrical equipment, reduce the risk of fires, and prevent electrostatic discharge damage.

To achieve these benefits, it is important to follow the right procedures when installing a grounding system. This includes selecting the correct grounding material, calculating the right amount of material needed for the building, and ensuring that the system is installed correctly. It is also important to maintain the grounding system by regularly testing it and repairing any damage that may occur.

Common Mistakes in Structural Steel Earthing

Unfortunately, there are some common mistakes that can be made when installing a grounding system. One of the most common mistakes is using insufficient grounding material, which can lead to a high resistance path for electric currents. Another mistake is failing to test the system regularly, which can lead to undetected damage and increased safety hazards.

The Importance of Testing Structural Steel Earthing

To ensure that your grounding system is functioning correctly, it is essential to test it regularly. One way to test the system is to use a clamp-on meter, which measures the amount of current flowing through the grounding system. If the current is too high, it may be an indication that the grounding system is not functioning correctly.

Proper Installation of Structural Steel Earthing

Another key factor in the proper installation of structural steel earthing is ensuring that the system is installed correctly. This includes selecting the right type of grounding material, calculating the amount needed for the building, and ensuring that the system is installed according to the manufacturer's instructions.

The Future of Structural Steel Earthing

As technology continues to advance, new materials and methods for structural steel earthing are emerging. One such development is the use of conductive cement, which can be used to create a low-resistance path for electrical currents. Another development is the use of earth clamps, which can be used to connect a grounding system to the earth without the need for drilling.

Question and Answer

Q: Why is structural steel earthing important?

A: Structural steel earthing is important because it helps to prevent safety hazards, legal liabilities, and damage to equipment by providing a low-resistance path for electric currents.

Q: What are some common mistakes made when installing a grounding system?

A: Some common mistakes include using insufficient grounding material, failing to test the system regularly, and not following the manufacturer's instructions for installation.

Q: How often should I test my grounding system?

A: It is recommended to test your grounding system at least once a year. However, if you notice any changes in the system's performance, such as increased resistance or higher current flow, you should test it immediately.

Q: What is the future of structural steel earthing?

A: The future of structural steel earthing involves the use of new materials and methods, such as conductive cement and earth clamps, to provide a low-resistance path for electric currents.

Conclusion of Structural Steel Earthing

In conclusion, structural steel earthing is a critical aspect of any construction project that involves electrical systems. By following the right procedures for installation and maintenance, you can prevent safety hazards, legal liabilities, and damage to equipment. Additionally, advancements in technology are leading to new materials and methods for structural steel earthing, which will continue to improve the safety and longevity of buildings for years to come.

Gallery

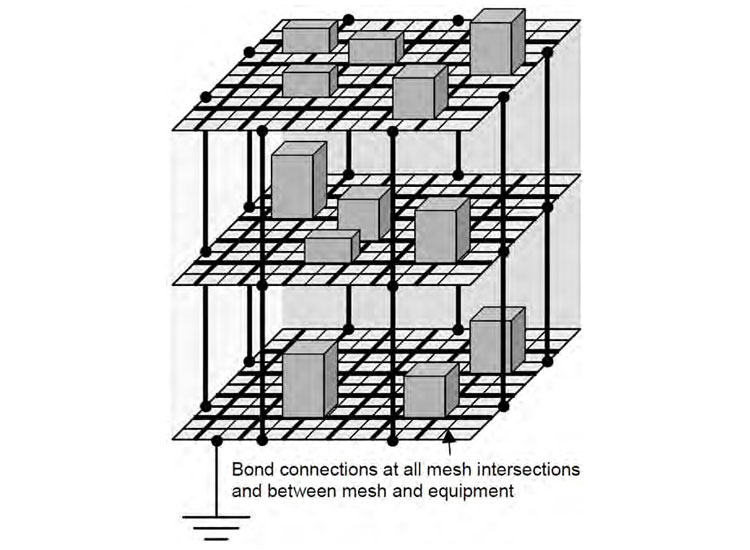

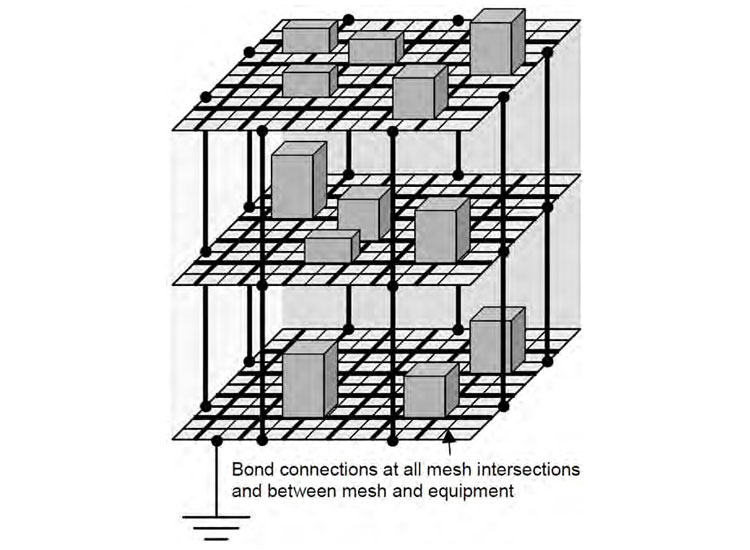

Q & A Of The Day - Can Structural Steel Can Be Bonded

Photo Credit by: bing.com / steel structural earthing protection bonded

What Are The NEC Requirements For Earthing And Bonding Rebar? - E&S

Photo Credit by: bing.com / bonding earthing rebar steel electrical nec

Gallery

Photo Credit by: bing.com / earthing

Where Can We Use Plate Earthing And Where To Use Pipe Earthing? - Quora

Photo Credit by: bing.com / earthing pipe systems equipment plate use where earth grounding rod pit houses methods bar types electric length copper cost galvanized

Structural Earthing - Newdestinare

Photo Credit by: bing.com / earthing building

0 Response to "Structural Steel Earthing"

Posting Komentar